Hello and welcome back to another installment of Basement Builds! I apologize for the long hiatus, I got real busy starting a new job and putting together a band. Most of my effort lately has gone towards writing new music so the tinkering has taken a real backseat. However, as I was working on a riff for a our newest song, I noticed the tone knob on my primary axe was coming loose. This wouldn’t be such an issue had I not just tightened this tone knob so I decided enough was enough and this pot had to go. Time to stop talking about my favorite guitarists and start playing like them.

Step 0: Decide You Need A Killswitch

A loose knob that has got to go.

This is the easiest step of the whole build. I still remember the first time I heard Tom Morello’s guitar solo in Bulls On Parade. I was so blown away that I started experimenting with the toggle switch on my own Univox Les Paul copy. Being a pretty cheap starter guitar I broke the toggle switch almost instantly by violently throwing it back and forth. I then asked my dad to help me wire a killswitch into an old patch cable and in that moment my whole life changed. I became much more excited about the guitar knowing that I could do these mods myself to completely change the instrument. I think it was that moment that sealed my fate and lead my to pursue a degree in engineering but that’s not important right now. We are here to talk about how to wire your own killswitch which brings my to step 1.

Step 1: Remove Tone Knob (optional)

I have labeled this step as optional because you do not have to remove the tone knob to add a killswitch. If you want to drill an additional hole in the body of your guitar and put the killswitch in that hole, by all means go for it. I don’t really use the tone knob on this guitar though and didn’t want to do any drilling so am using the existing hole.

The tone knob is quite easy to remove. Simply pull the knob off the shaft and the remove the nut and washer. The remaining part of the tone knob (the potentiometer) may fall into the body of the guitar but that is okay. we will be opening the back in just a minute to get that out.

Finally, take the back panel off your guitar, pull the potentiomenter out of the whole, put the nut and washer you removed back on for safe keeping and use a dab of glue to secure the potentiometer out of the way. The potentiometer can be removed entirely if you are good with wiring but this is a very risky move and could end up costing you a lot if mess up and have to get something repaired.

Step 2: Add Button

Secure the button tighter than the knob

Once the tone know is removed and out of the way we add a button to the hole that is now vacant. I used a little bit of Loctite and some pliers to make sure the button would not come loose like my tone knob did. It is very important that you use a normally open momentary switch. Any other type of switch will have to be wired differently. Normally open means that current will not pass through the switch until the button is pressed. Momentary means the switch will not ‘lock’ into place when the button is pressed like a guitar pedal would. Here I should have included sketches of my circuit but I did not plan this build out like my others. This was an impulse build that I did out of frustration towards the loose tone knob. I do not recommend winging your guitar mods unless you also have a degree in engineering but if you also have a degree in engineering then you already know better than to go about projects without a plan.

Step 3: Wire Button

b.eng not required but recommended

Once the button is securely in place, you will need to wire it up. This is where it is important to know what kind of switch you have. Since I have a normally open switch I had to wire it in a way that would not effect the signal passing through the guitar until the button was pressed down. To do this, I connected the two leads on the button to the two terminals of the input jack. When the button is not being pressed the two terminals of the input jack are not connected and the signal will pass through the electronics of the guitar as it normally would. When the button is pressed it will create a short between the two terminals of the input jack creating a path of less resistance. Now given the option of passing through the button or passing through all of the guitar’s electronics, the signal will choose the button thereby ‘killing’ the guitar. I put a little but of red electrical tape over one of the terminals of the button so there would be no chance of the two leads touching each other and turning my switch into an always-closed instead of normally-open.

Step 4: Rock Like Your Heroes

Now that your kill switch is wired up you can put the back panel back on and rock out like your favorite killswitch-using guitarists. Leave a comment and let me know who inspired YOU to install a killswitch.

I have designed this pedal to be as simple as possible with very few parts so you don’t need to be a world-class physicist to put it together.

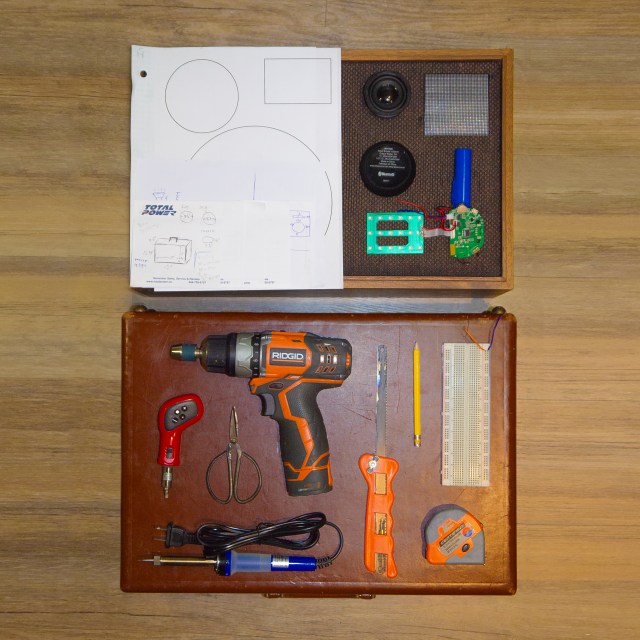

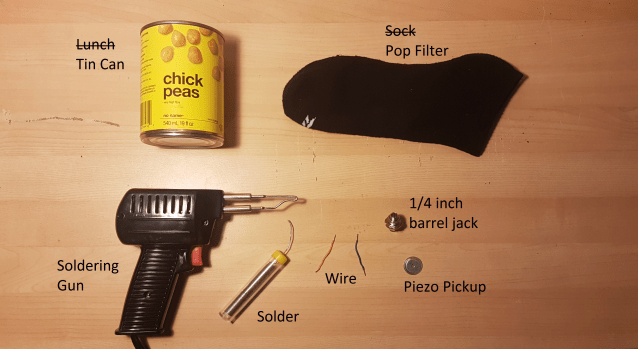

I have designed this pedal to be as simple as possible with very few parts so you don’t need to be a world-class physicist to put it together. The first thing you will need to do is gather your parts. As with the microphone, most of these parts can be found in your home but I will try to link as much as possible to be safe.

The first thing you will need to do is gather your parts. As with the microphone, most of these parts can be found in your home but I will try to link as much as possible to be safe.

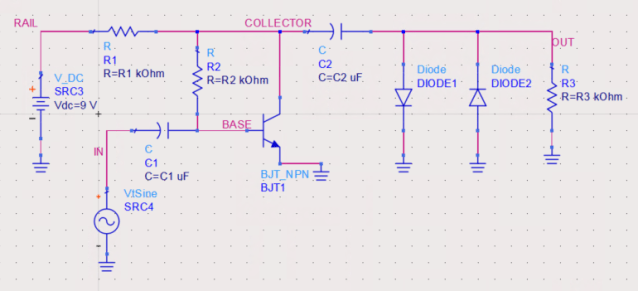

If your board does not have any of the holes connected you will have to make groupings for nodes yourself. Finally, pick groups of holes that are near each other, but not too close, and label them as your nodes.

If your board does not have any of the holes connected you will have to make groupings for nodes yourself. Finally, pick groups of holes that are near each other, but not too close, and label them as your nodes. It is also a good idea at this point to sketch you components right in the board using your nodes as a reference. I like to do this on paper with a pencil because it can take a few tries to get a nice arrangement. We can see in the sketch to the left that I had trouble grounding all my parts at the output. To make this easier I connected a group of holes to the negative rail using a short wire.

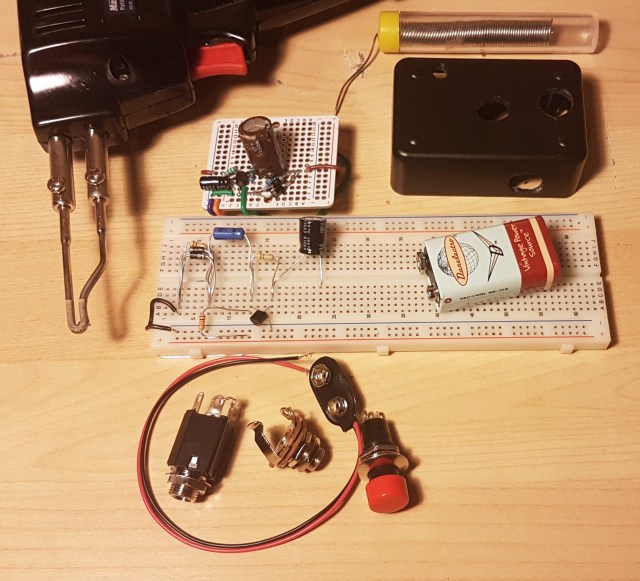

It is also a good idea at this point to sketch you components right in the board using your nodes as a reference. I like to do this on paper with a pencil because it can take a few tries to get a nice arrangement. We can see in the sketch to the left that I had trouble grounding all my parts at the output. To make this easier I connected a group of holes to the negative rail using a short wire. It is always a good idea to test a circuit before soldering it together. Testing can be difficult without expensive lab equipment which is why I have made this step optional. Start by putting your parts on a breadboard in accordance to your sketches.

It is always a good idea to test a circuit before soldering it together. Testing can be difficult without expensive lab equipment which is why I have made this step optional. Start by putting your parts on a breadboard in accordance to your sketches.

If you skipped the last step, soldering might not appeal to you either but rest assured as it is not completely necessary. You can leave your pedal completely exposed on a breadboard if you wish. You will simply need to replace the VSG with a 1/4” Jack and the PSU with a 9V battery snap. The other 1/4” Jack will go in parallel with the diodes and R3. Take a look at my circuit if you’re having trouble and try to draw it out. I used

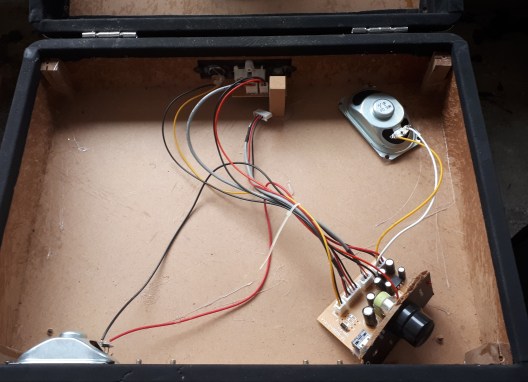

If you skipped the last step, soldering might not appeal to you either but rest assured as it is not completely necessary. You can leave your pedal completely exposed on a breadboard if you wish. You will simply need to replace the VSG with a 1/4” Jack and the PSU with a 9V battery snap. The other 1/4” Jack will go in parallel with the diodes and R3. Take a look at my circuit if you’re having trouble and try to draw it out. I used  To keep everything safe it is a good idea to put your guitar pedal in a box. I put mine in a old bell box with a button on it. If you put a button in your pedal you will need to connect either end of it to the two positive parts of the 1/4” jacks. The positive parts are the ones that make connection with the patch cable.

To keep everything safe it is a good idea to put your guitar pedal in a box. I put mine in a old bell box with a button on it. If you put a button in your pedal you will need to connect either end of it to the two positive parts of the 1/4” jacks. The positive parts are the ones that make connection with the patch cable.  The button will allow you to toggle on bypass by creating a short from input to output. Make sure to place your board in the box and feed your loose wires through the appropriate holes before soldering the button, battery, or 1/4” jacks. Finish it off by pulling the excess wire into the box and fastening the jacks and button in place.

The button will allow you to toggle on bypass by creating a short from input to output. Make sure to place your board in the box and feed your loose wires through the appropriate holes before soldering the button, battery, or 1/4” jacks. Finish it off by pulling the excess wire into the box and fastening the jacks and button in place.

The first thing you will have to do is get the can ready to act as the housing for your microphone. You can use any can that you like but I recommend choosing a sturdy can that fits well in your hand or gig bag. Once you have emptied and cleaned your can you need to pierce a hole in the side or bottom. I chose the side so the mic could be set down while in use. The hole will have to be just large enough for the end of the barrel jack to stick through snugly. Be careful not to make the hole too large or you will have trouble getting the jack to stay.

The first thing you will have to do is get the can ready to act as the housing for your microphone. You can use any can that you like but I recommend choosing a sturdy can that fits well in your hand or gig bag. Once you have emptied and cleaned your can you need to pierce a hole in the side or bottom. I chose the side so the mic could be set down while in use. The hole will have to be just large enough for the end of the barrel jack to stick through snugly. Be careful not to make the hole too large or you will have trouble getting the jack to stay.

With leads on your pickup, it is ready to be attached to the barrel jack. You will need to affix the two leads from the pickup to the two wings on the barrel jack. It should not matter which lead goes on which wing so long as you attach one to each. If you are not comfortable with soldering this step can be done without so long as you got a pickup with leads and skipped the last step. Simply feed the wire through the hole, fold it back, and give it a little twist.

With leads on your pickup, it is ready to be attached to the barrel jack. You will need to affix the two leads from the pickup to the two wings on the barrel jack. It should not matter which lead goes on which wing so long as you attach one to each. If you are not comfortable with soldering this step can be done without so long as you got a pickup with leads and skipped the last step. Simply feed the wire through the hole, fold it back, and give it a little twist.  Those of you conformable with soldering should add a little bit here to increase the durability of the connection. Finally wrap the connection in electrical tape or shrink-wrap to finish it off an avoid shorts.

Those of you conformable with soldering should add a little bit here to increase the durability of the connection. Finally wrap the connection in electrical tape or shrink-wrap to finish it off an avoid shorts. Now all of the components are ready to go and the final step is assembling your microphone. This part can be a bit tricky if you have big hands like me and cannot get them inside your can. Needle nose pliers can be quite helpful here. First, take one nut and the washer off of your barrel jack. Then feed the end through the hole in the can and fasten the washer and nut back on the jack from the outside of the can. This should hold the jack firmly in place. Next, using a piece of double-sided tape (or any adhesive of your choosing) secure the pickup to the bottom of the can. Finally, stuff the thin sock into the can, toe end first, and fold the top down over the rim of the can. This will not only cover the possible sharp edge but also act as a pop filter for better sound quality.

Now all of the components are ready to go and the final step is assembling your microphone. This part can be a bit tricky if you have big hands like me and cannot get them inside your can. Needle nose pliers can be quite helpful here. First, take one nut and the washer off of your barrel jack. Then feed the end through the hole in the can and fasten the washer and nut back on the jack from the outside of the can. This should hold the jack firmly in place. Next, using a piece of double-sided tape (or any adhesive of your choosing) secure the pickup to the bottom of the can. Finally, stuff the thin sock into the can, toe end first, and fold the top down over the rim of the can. This will not only cover the possible sharp edge but also act as a pop filter for better sound quality.